Automated Precision in Pipe Welding – How We Work with Orbital Technology at GYGV

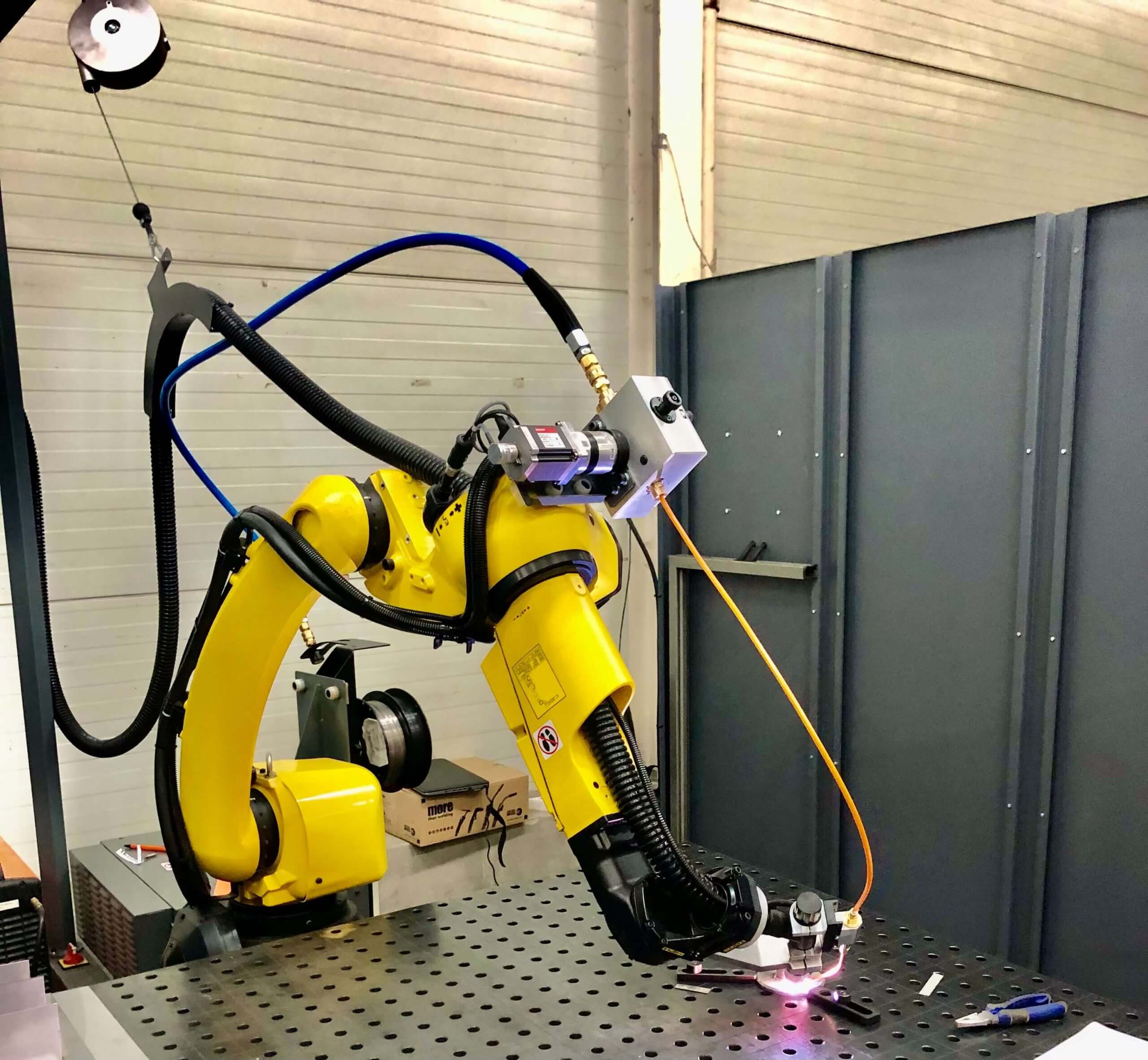

Advanced technologies are playing an increasingly important role in industrial pipe welding. At GYGV, we rely on these solutions as well: with our four orbital welding machines, we deliver accurate and reliable results for pipe diameters ranging from 8 mm to 168.3 mm. This fully automated system is the ideal choice in applications where the … Olvass tovább