At GYGV Kanizsa, we use advanced pipe collaring technology (also known as neck forming) to manufacture stainless steel manifolds for various industrial applications.

This process allows us to create accurate, leak-proof branch connections on main pipes without full-penetration welding, enhancing the mechanical strength, hygiene, and durability of the assemblies.

Why is pipe collaring technology advantageous?

- No full-penetration weld seam → no dead spots or unfavorable turbulence

- Hygienic surface, ideal for food and pharmaceutical systems

- Additional connections can be welded with orbital tube welding

- High dimensional accuracy, even in serial production

- Faster production time compared to separate branch fittings and welding

What sizes and configurations can we produce?

Our pipe collaring machine covers the following range:

-

Main pipe diameter: Ø33.7–323.9 mm / 1”–12”

-

Formed branch diameter: Ø21.3–114.3 mm / ½”–4”

This size range covers most industrial, food & beverage, pharmaceutical, chemical, and mechanical engineering applications, from smaller DN50 branches up to larger DN200–80 configurations.

Where can it be applied?

-

Distribution of liquid and gas pipelines

-

Branches on pressure vessels

-

Heat exchangers and process pipework

-

Automotive and mechanical engineering solutions

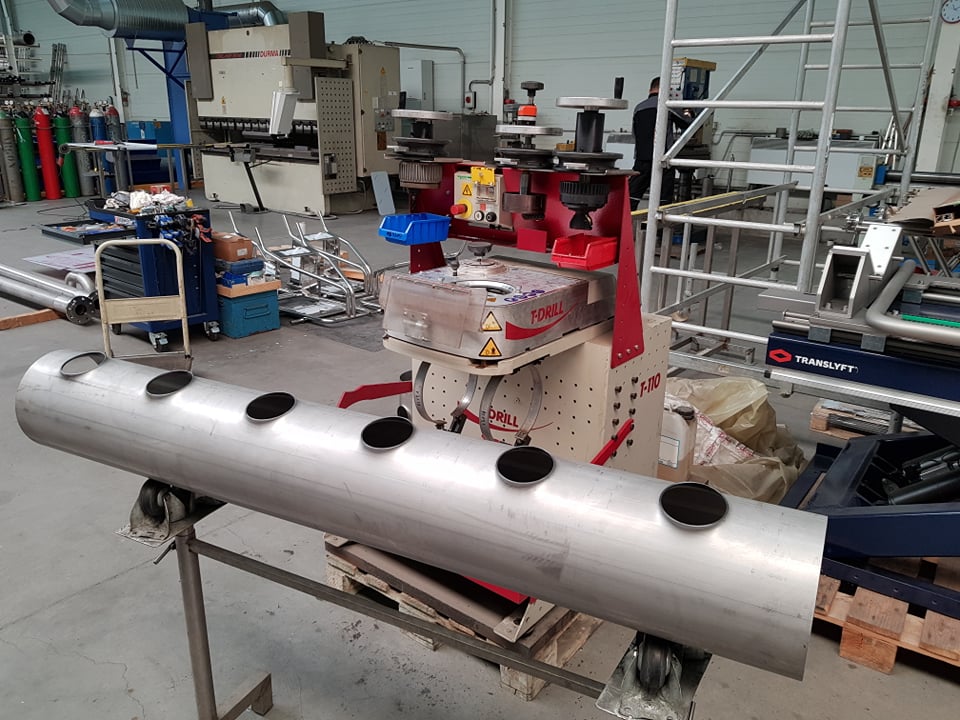

Example from a recent project

We recently manufactured a DN200–80 stainless steel manifold, where a DN80 branch was formed directly from the main pipe.

By maintaining material continuity, the manifold achieved high pressure resistance and outstanding durability – completed in a single forming operation, without any weld seams.